Question: Describe Solvay process.

Answer.

Solvay Process

A process in which sodium carbonate is obtained from lime stone, ammonia and brine is known as Solvay process.

Solvay Process consists of following steps

1. Preparation of Ammonical Brine

Ammonical brine is prepared by dissolving ammonia gas in brine. Ammonical brine is transferred into carbonating tower

2. Carbonation

In carbonating tower, carbon dioxide is passed through ammonical brine and following reaction take place.

At the bottom of tower, NaHCO3 is precipitated out by keeping temperature at 15 Oc.

3. Filtration

Precipitates of NaHCO3 are separated from the milky solution by filtration. It is used as baking soda.

4. Calcination

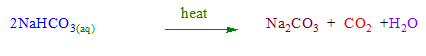

Sodium hydrogen carbonate is heated to get sodium carbonate.

Carbon dioxide released is re-cycled in the process.

5. Preparation of Carbon dioxide and slaked line

Carbon dioxide is produced by heating the lime stone in kiln.

CO2 is fed into the carbonating tower from top and equal amounts of lime (CaO) and water are mixed to prepare the slaked lime.

Slaked lime is pumped to the ammonia recovery tower.

6. Recovery of Ammonia

Solution containing ammonium chloride produced during carbonation is heated with slaked lime

With almost all ammonia is recovered in the process.

Advantages of Solvay Process

The raw material for Solvay process is cheap and easily available.

It is pollution free process and no harmful products are produced.

It requires as less fuel as it does not require evaporation of solvent.

Ammonia and carbon dioxide are recovered and reused in the process.

Products like NaHCO3 and Na2CO3 produced in this process are highly pure.

Comments

Post a Comment